GST : 33AQOPS0137N1ZG

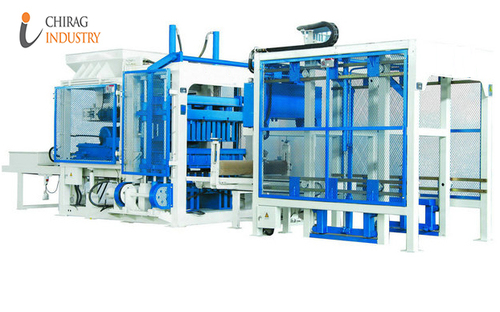

Hydraulic concrete block making machine manufacture in coimbatore

Product Details:

- Product Type semi automatic

- General Use construction

- Method Hydraulic Pressure

- Processing Brick Production Line

- Automatic No

- Power 30 kw

- Voltage 440 Volt (v)

- Click to View more

Hydraulic concrete block making machine manufacture in coimbatore Price And Quantity

- 1 Piece

- 4500000.00 - 5000000.00 INR/Piece

- 4500000.00 INR/Piece

Hydraulic concrete block making machine manufacture in coimbatore Product Specifications

- Hydraulic Pressure

- 30 kw

- Brick Production Line

- Cement

- No

- construction

- grey,ivary

- 1 year

- Hollow Block Making Machine

- 14 Pcs/min

- 8 Tonne

- semi automatic

- 4000*3600*2550 Millimeter (mm)

- 440 Volt (v)

Hydraulic concrete block making machine manufacture in coimbatore Trade Information

- Coimbatore

- 1 Piece Per Day

- 5 Days

- Plastic bubble cover packing

- Asia

- All India

Product Description

Main Technical

Compulsive feeding device: When feeder transport above mold box, the mixing blades start rotating, keep the material feed uniform and the products with same density.

PLC control and dialogue system of human-machine interface, easy to analyze the chance signal, ensure the best operation effect.

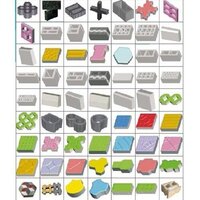

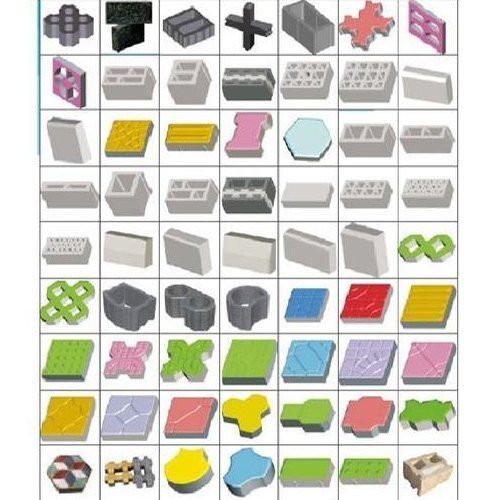

Multi-purpose change different mold can produce various kinds of hollow blocks, porous blocks, solid bricks color pavers revetment bricks, Products withs high compressive strength. Performance and Parameters

CI-4-20-FA Hydraulic Block Forming Machine is one kind of advanced equipment, which is ofhydraulic-mechanical integration and dialogue between man and machine controlled by computer system this machine is developed according to international development tide and designed for domestic situation which can be operated without any simple training.

Made of high-strength steel and by special welding procedure, this machine is very firm. its guiding columns are made of special super strong steel, which surfaces are coated with cadmium, and have perfect torsional strength and wearing capacity. Its material distributor, using sensor and hydraulic proportional driving technologies, can produce forced centrifugal discharging under the function of swing and arc-breaking mechanism to provide quick and even material distributing, specially suitable for producing thin wall and perforated block. Under the control of computer, the material distributer can produce vertical synchronous vibration by hydraulic driving system to carry out low and perforated blocks. Under the control of computer the material distributor can produce vertical synchronous vibration by hydraulic driving system to carry out low frequency material distributing and highfrequency block forming. And its multi-source vibrating system can give perfect vibrating effect to differ raw material. MODEL CYCLE TIME (S) PALLET SIZE(MM)

Call Me Free

Call Me Free